Iridium, copper, platinum, multi-electrode, single-electrode, plutonium, space dust! The list of spark plug options can be daunting at first glance. Many manufacturers claim their spark plugs will boost performance and increase mileage. Online preachers will swear that their $20 quad-iridium-tip plugs will yield 21.256 extra HP. The truth is, the spark plug has one job: sparking. If it sparks, its job is done. Granted, there is a marginal amount of power to be gained from a larger, more intense spark—but usually this gain is quite minimal.

Heat Range

OK, I lied—the spark plug actually has two jobs. In addition to igniting the in-cylinder mixture, the spark plug also sheds heat away from the combustion chamber. It does this by conducting heat through the core of the spark plug, through its threads, and into the coolant in the cylinder head. The core of the spark plug is insulated from its threads by a layer of ceramic. The thicker this ceramic is, the less heat the spark plug will conduct into the head, and the “hotter” the plug is said to be. The thinner the ceramic insulation, the more heat it can shed, and the “colder” it is said to be.

A spark plug is designed to run within a specific temperature range in order to clean itself of carbon buildup. If it doesn’t get hot enough, it will foul with carbon and cease to function. If it gets too hot, it can act as a source of pre-ignition and cause knock. Therefore, spark plug heat range choice is very important.

The stock plug from Volvo is a Bosch heat range 7 plug. For high-performance applications, it is recommended to go one step colder to a heat range 6 plug. The increased heat from higher engine output and periodic full-throttle runs will allow the colder plug to reach a high enough temperature to clean itself of carbon. Going two steps colder will shed more heat from the combustion chamber, but in practice this performance benefit usually isn’t significant—and the spark plug can end up too cold, which can cause carbon fouling.

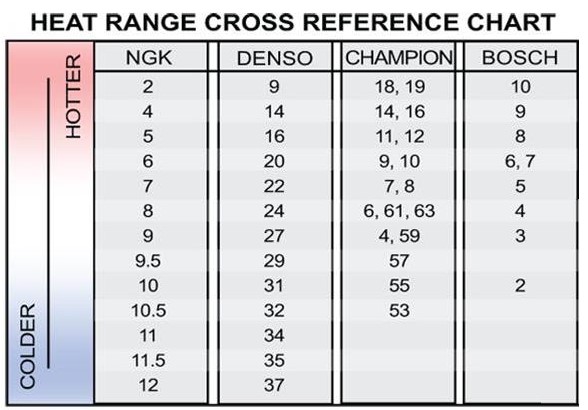

Keep in mind that manufacturers use different heat range scales. See the chart below for cross reference.

Center Electrode

The debate rages on about the best center electrode material. The main factor in electrode material choice is service life. An iridium spark plug will typically need to be replaced less frequently than a platinum plug, and a platinum plug will typically need to be replaced less frequently than a copper plug. Performance-wise, all plugs perform roughly equivalently, so the selection comes down to cost and how frequently you want to change plugs. There are arguments about the largest gap attainable versus electrode selection, but in practice spark output is fairly similar across electrode materials.

Blowout

A very common problem encountered with increased boost pressure is spark blowout. A bit of a misnomer, spark blowout isn’t the spark being “blown out,” but rather the spark being unable to form. This causes a misfire—or more accurately, a missed combustion event due to a lack of spark. This missed combustion event is very noticeable and can be unsettling to those unaccustomed to the problem. It can best be described as sounding like muffled machine gun fire, accompanied by a jerky, and quite apparent, loss of power.

In the vast majority of cases, spark blowout is non-harmful, albeit very power-robbing. Prolonged spark blowout can cause raw, unburned fuel to wash down the cylinders and contaminate the oil, but usually the issue doesn’t occur frequently enough to be a significant problem. Spark blowout typically occurs at peak torque, when cylinder filling is at peak density. For TD04-frame turbos, this usually occurs between 4200–5500 RPM.

Blowout is named as such because of the way a spark forms. When the air/fuel mixture becomes electrically charged beyond its point of electrical breakdown, charge will leak from the center electrode into the surrounding gas. This charge leakage forms a coronal cloud that propagates from the spark plug’s electrode until it reaches the spark plug’s ground strap. At that point, a conductive channel is created and the spark forms. Blowout occurs when the coronal cloud is “blown out” and can’t reach the ground strap.

The speed at which the coronal cloud moves is directly related to the available spark energy and the dielectric strength of the medium it’s traveling through. In the case of an engine, the “power” is the voltage at the tip of the electrode, and the dielectric medium is the air + gasoline mixture inside the cylinder. As boost pressure increases, the density of the air/fuel mixture increases, which increases dielectric strength and slows the propagation of the coronal cloud. When in-cylinder density increases past the point at which the available voltage is sufficient to bridge the spark gap, the spark will not form and blowout will occur.

When spark plug blowout is encountered, the first thing that should be checked is the condition of the ignition components. On a distributor-equipped car, the cap, rotor, and spark plug wires add resistance to the energy traveling from the ignition coil to the spark plug. This resistance increases as the components age, so it is important to stay on top of regular service intervals for their replacement.

If the ignition components are in good condition but spark blowout is still present, the spark plug gap can be decreased. It is always ideal to run as wide a spark plug gap as possible. The wider the gap, the larger the spark, and the faster the burn—meaning more power can be extracted from the combustion event. However, a compromise must be made between spark gap and spark blowout. If the gap is too wide, spark blowout is more likely to occur. Ideally, you want the widest gap that still allows a spark to form under all engine operating conditions.

How to Prevent Spark Blowout

Spark Gap

If spark blowout is encountered, the first thing that should be checked is spark plug age and spark gap. The stock spark plug gap for most plugs compatible with a turbocharged whiteblock is anywhere from .031″–.035″. This is much too large for tuned setups, and one is almost guaranteed to encounter spark blowout if plugs are installed without first reducing the gap.

Ideally, you can run a spark plug gap of .028″ if all ignition components are in excellent condition. However, even this gap can still sometimes allow for spark blowout, which would mean removing the plugs and re-gapping them. To save yourself the headache of removing and adjusting the gap multiple times, I recommend setting the gap to .024″. The difference in power output between .028″ and .024″ is quite minimal. However, if after tuning you want to experiment, you can always increase the gap.

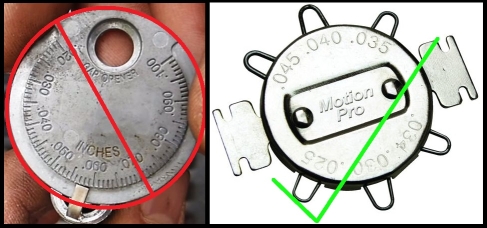

To gap a spark plug, feeler gauges or a purpose-made spark plug wire gauge should be used—do not use a “coin-gapper,” as they can be very inaccurate. Measure the gap, and if the gap needs to be widened, use pliers to gently pry the ground strap away from the electrode. Do not try to pry with anything between the electrode and the ground strap, as this can damage the electrode.

I recommend applying copper anti-seize to the spark plug threads and torquing them to 21 ft-lbs.

Replace or Upgrade Ignition Components

If the plugs are found to be old, they should be replaced. I recommend NGK BKR7E, stock #4644. These plugs are inexpensive, easily available copper plugs that are one heat range colder than stock. If you prefer iridium plugs, you can use NGK #2667, which are also one step colder. For those running “RN” R cylinder heads that require longer spark plugs, and who want one step colder plugs, you can use NGK #2309.

If replacing the spark plugs and setting the correct gap does not fix the spark blowout, then the ignition cap, rotor, and spark plug wires should be replaced. For the cap and rotor, make sure to use OEM Bosch. For spark plug wires, Bougicord or IPD’s performance wire set are recommended.

If spark blowout persists even after changing all other ignition components, then you should replace your ignition coil. The MSD Blaster coil is an equivalent replacement for the factory Bosch coil and is typically a bit less expensive. It has similar performance to the factory coil, so it isn’t much of an upgrade. The MSD coil has different dwell (charge time) characteristics than the factory coil, so the tune must be updated to account for this. Otherwise, the coil can be overcharged and may have a shorter lifespan.