The factory fuel pump wiring on P80 Volvos is insufficient at providing enough power for upgraded fuel pumps. As counter intuitive as it may seem, sometimes upgrading a fuel pump without upgrading the wiring can actually decrease fuel flow. This is because larger pumps require more power to flow the same equivalent amount of fuel as smaller pumps, due to their larger impeller. Therefore, it is recommended to upgrade the fuel pump wiring anytime an aftermarket fuel pump is installed, even if you are still running a stock turbo. Upgrading the fuel pump wiring also has the added benefit of prolonging the life of the failure prone fuel pump relay, as it will no longer need to supply as much power.

If you want proof that your fuel pump wiring needs to be upgraded, check the voltage at the fuel pump connector and compare this to the voltage at the battery, while the engine is idling. Most likely, you’ll see that you a .5V or greater drop between the two. Considering that fuel requirements at idle are significantly less than at wide open throttle, a .5V drop at idle could be equivalent to a 3V drop at WOT, which would be equal to a 20% loss of fuel flow!

The following instructions are for installing the Deatschwerks FPHWK fuel pump wiring kit, but the instructions will be similar for any type of relay based, fuel pump wiring upgrade kit used. You can purchase the FPHWK kit here:

https://www.vasttuning.com/product/deatschwerks-fuel-pump-hardwire-kit/

Before starting any work on the fuel system, unplug the battery!

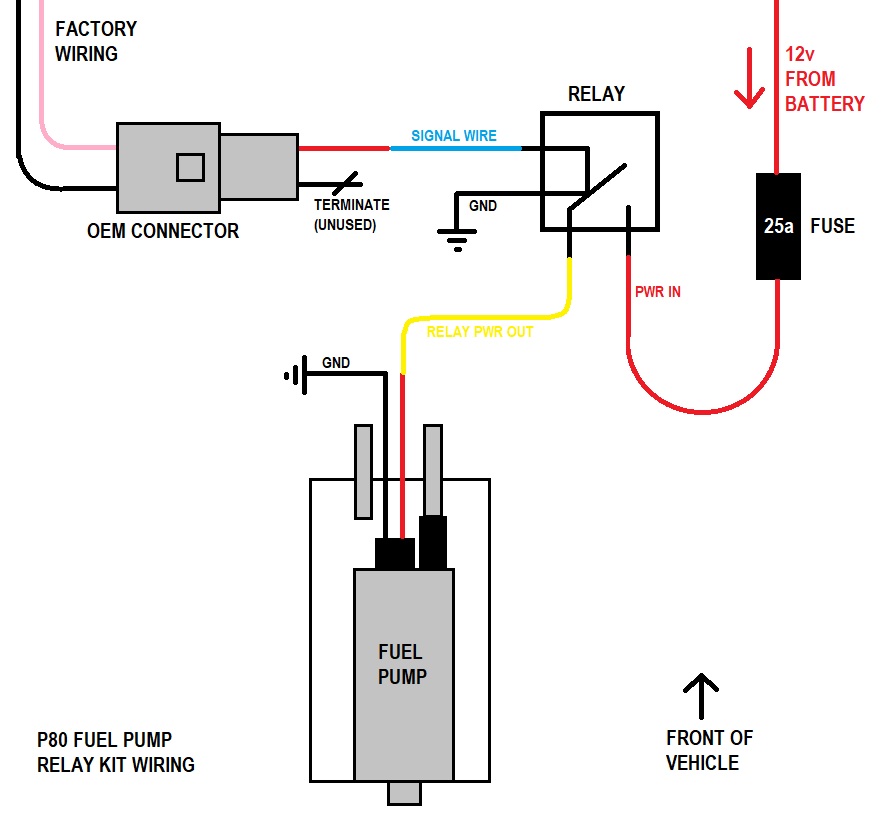

This kit is a substitution for your factory fuel pump wiring and will provide a direct power supply from the battery to your fuel pump. This kit uses a relay, which is a power switch, that receives its signal from your factory fuel pump wiring to turn on when the key is put into ignition pos. II. This closes the connection between a new the battery and fuel pump via a direct 12v line, eliminating the path through the small diameter factory wiring and fuel pump relay, which results in less voltage drop.

This diagram above shows how the relay is added to the factory circuit. Note how the grey OEM connector is used to provide a “signal” to the relay. The factory power wire (pink/red) connects to the blue relay wire to activate the relay when the car is on. The black wire (factory fuel pump ground) coming out of this connector can simply be cut and left disconnected. You will have a constant 12v power coming into the relay (red wire) and a switched 12v out of the relay (yellow), which will connect to the power wire (red) on the fuel sending unit/pump. It is important to also bypass the factory ground wire when upgrading. Both the fuel sending/pump unit and relay have black ground wires that you will want to connect to a solid, bare metal surface in the trunk with ring terminals.

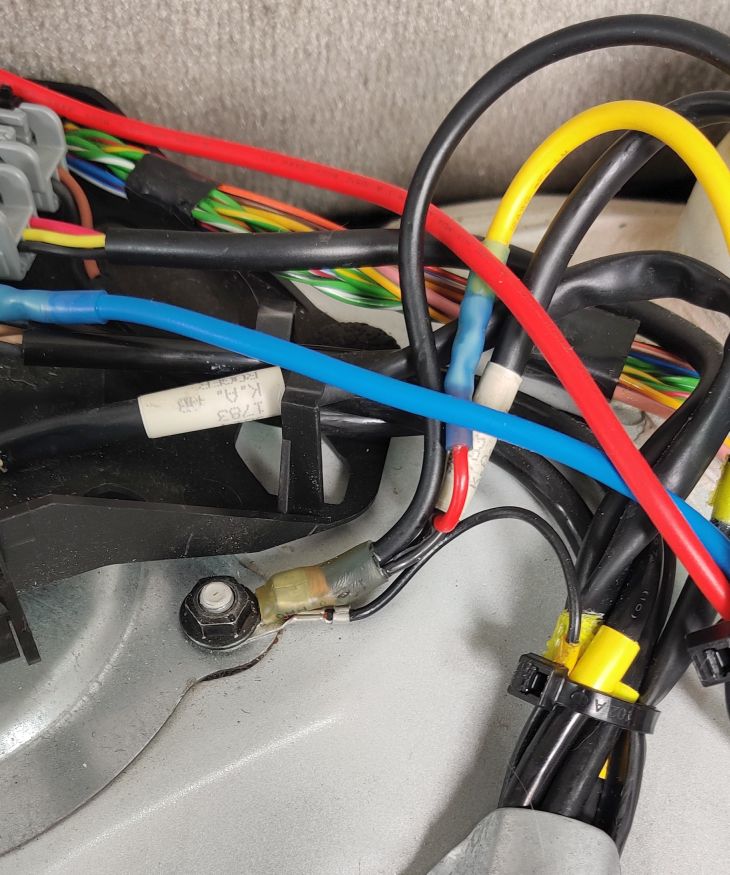

The first thing to do is to run the power wire through the interior. Cut the red wire at the splice which connects to the fuse. Pull the cut end of the wire through the firewall passthrough, shown in the next two pictures. This power wire is critical for the car to run, so you want to make sure that the wire is run inside the car.

Reconnect the splice to the fuse and crimp a ring terminal onto the end. Secure the ring terminal onto the battery connector, under the 10mm bolt. Leave the fuse out until everything is wired.

To make running the wire into the trunk easier you can remove the red wire from the relay plug by depressing the pin lock in the connector with a small flat blade screw driver.

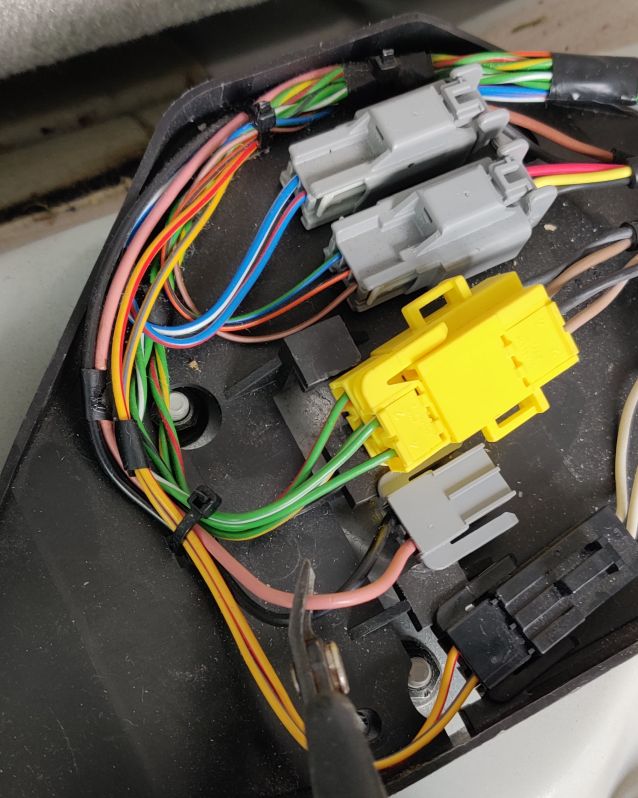

In the trunk, under the floor behind the rear seats, you will find the blow pictured collection of plugs/connectors. The grey two pin connector is the power supply for the fuel pump. Cut the pink wire, leaving a short length of wire going to the plug, so that you can repair the cut should you ever want to return the car to stock.

This is a picture of the relay mounted in the trunk. The blue signal wire and yellow power-out wire are short, so you’ll want to place the relay close to the fuel pump connector.

The black wire from the relay and black wire coming from the fuel pump sender should be connected to one ring terminal and grounding at the below pictured location

Installing the Relay in the Trunk

To test the relay is working, turn your key to POS. II and listen for the relay to click on and your fuel pump should begin pressurizing the system. You will need to cycle this a few times before the car will start. Then, let it idle for a bit and make sure the engine stays running.