Motronic 4.4, along with most engine management systems, uses a combination of mechanical and electronic systems to control boost pressure.

This article explains:

- What actually controls boost on your car

- How the Turbo Control Valve (TCV) and wastegate interact

- Why wastegate preload matters

- How the target boost level in the tune relates to hardware setup

1. The Three Pieces that Control Boost

Boost control is dependent on these three components:

- Wastegate actuator (spring strength and preload)

- Turbo Control Valve (electronic control)

- ECU calibration

You can think of boost control as a combination:

- Wastegate spring strength and preload sets the minimum boost

- The TCV allows for more boost

- The ECU decides how much boost to request

2. Wastegate Actuator: The Mechanical Baseline

The wastegate actuator is a spring-loaded, pneumatic actuator that opens the wastegate when boost pressure overcomes the spring force and preload of the actuator. On stock turbos, the boost pressure source comes from a nipple on the face of the turbo compressor. For some larger than stock turbos, there is no nipple on the turbo’s compressor cover, in which case the boost pressure from the intake manifold is used.

With the TCV unplugged or no boost command from the ECU, boost pressure will flow unobstructed into the actuator and the turbo will make base boost only – the minimum amount of boost that the car is capable of making. This base boost level can also be referred to as wastegate boost.

- The wastegate boost level is dictated by:

- Turbo Size

- Actuator spring strength

- Actuator preload

- Actuator diaphragm size

- Exhaust Backpressure

Proper wastegate actuator spring selection and preload setting is an essential step in getting a car ready to be tuned.

- Too weak of a spring → slow spool, low peak boost

- Too strong of a spring → fast spool, limited boost control by the ECU and excessive peak boost

- Too little preload → slow spool, unstable boost, poor control

- Too much preload → boost spikes, over-boost, poor control

3. Turbo Control Valve (TCV): How the ECU Raises Boost

The TCV is a 3-port solenoid valve that the ECU pulses to control how much pressure reaches the wastegate actuator. The TCV can only increase the boost level.

The TCV receives a square wave PWM signal from the ECU – the boost command. This control signal is analogous to flipping a light switch on and off rapidly. By varying the ratio of how much time the signal is on vs off, the amount of boost pressure that reaches the wastegate actuator can be altered. The ratio of on to off time is called the duty cycle, or simply duty.

In simple terms:

- More TCV duty → less pressure to the actuator → more boost

- Less TCV duty → more pressure → lower boost

The ECU does not directly control boost—it controls pressure to the actuator.

4. ECU Boost Targets (Bosch M4.4 Logic)

A common misconception is that installing a manual boost control (MBC) can increase performance, as compared to having the ECU control boost. With the ECU in control of the boost level (and a proper tune), there will be no reduction in peak performance as compared to a MBC. Since the boost level will change with respect to the throttle position, leaving boost control up to the ECU makes the car much easier to drive.

The M4.4 ECU dictates the boost level dependent on engine RPM and throttle position. In addition, the ECU can decide to reduce the boost level in response to detonation or excessive coolant temps, thus protecting the engine.

The goal of a perfectly tuned boost map is to make a turbo charged engine feel like a powerful naturally aspirated engine. The engine’s power output should feel linear, as compared to the throttle position. Imagine the scenario in which you are driving up a steep hill and want to accelerate at a constant rate. With a MBC controlling boost, as the RPM rises, so will the boost level. To keep the acceleration rate constant, you’ll have to roll off the throttle. However, with the ECU in control of the boost level, a lower boost level will be commanded, due to low throttle position. Therefore, the throttle will be able to be kept at a constant position. When you extrapolate this to behavior across all driving conditions, you can imagine how much easier control of the car becomes.

5. Wastegate Preload vs Tune: How They Work Together

A common misconception is that more preload = more boost. In reality, there is an ideal wastegate preload setting that will result in the highest level of throttle control and driveability, with no reduction in peak performance.

A common thought is that if the current boost is under the desired target, then the preload should be adjusted to compensate. In actuality, the wastegate actuator preload has a very narrow range of ‘proper’ adjustment. If the desired boost profile can’t be achieved with the actuator properly preloaded, then the actuator’s spring tension should be changed.

Another common misconception is that the wastegate preload should be set based on pressure. Wastegate actuator preload should be set by tension only. If the preload is set based on pressure, then it is possible to set the actuator with too little, or too much preload. For a sanity check, the cracking and fully open pressure can be verified after the actuator preload has been set by tension.

It is very important that the actuator is set with the proper amount of preload, as improper preload can result in poor boost control. If the preload is too great, then the wastegate will not be able to fully open and the boost level will creep at higher RPMs. If the preload is too little, then exhaust gas back pressure will be able to open the wastegate, slowing spool and reducing peak boost.

Take for example a weak actuator, that when properly preloaded is fully open at only 4psi. If the preload on this actuator was set by pressure to be fully open at 10psi, then its range of movement would be severely limited and boost control would greatly suffer. Conversely, imagine a very stiff actuator that was set with too little preload. It wouldn’t be able to stay closed when desired, slowing turbo spool.

7. The First Step When Starting a New Tune

The base tune that is given to every new setup is configured with no boost command. Once it is established that the car is mechanically sound and running well, and the wastegate is properly preloaded, a 3rd gear full throttle pull is requested. Given the lack of boost command from the ECU, the wastegate boost level can thus be verified.

Ideally, the wastegate boost level should be 40-50% that of the target peak boost level.

- 15g/16t – 17psi target peak boost – 7-9psi wastegate boost

- 18t/19t – 20psi target peak boost – 8-10psi wastegate boost

- 20t/21tk/22t/K24 – 24psi target peak boost – 10-12psi wastegate boost

- 20G – 30psi target peak boost – 12-15psi wastegate boost

If the boost level is less than desired, then the wastegate actuator’s spring tension should be changed. If a wastegate actuator without a changeable spring is fitted, then one will need to be purchased. There are three options:

- For those with an angled flange turbine housing installed:

- For those with either a straight or angled flange:

If purchasing an actuator without a spring assortment, then it is worth getting an additional spring, just in case the spring needs to be swapped to achieve the correct wastegate boost level. For the Kinugawa and Forge actuators, purchasing the 1 and .8 bar springs is recommended.

The pressure rating of a wastegate spring is not equal to the wastegate boost level. Furthermore, the pressure rating of a spring varies by manufacturer, so a 1 bar spring from one manufacturer may result in a different boost level as compared to a 1 bar spring from a different manufacturer.

Another factor that influences the relationship between spring tension and the boost level is the area of the wastegate actuator’s diaphragm. Some wastegate actuators have a larger diaphragm, which means that they will exert a greater amount of force, given the same amount of boost pressure.

8. How to Set Wastegate Preload by Tension

This YouTube video explains how to set the actuator by preload:

For those with a K24: Establishing the point of zero preload is made difficult as the arm can’t be unscrewed from the flapper. To establish the point of zero preload, unscrew the adjuster nut until there’s free slack in the assembly. Don’t unscrew the knurled adjustment nut entirely, just until the point at which you can jiggle the wastegate arm freely. Then, unbolt the two 10mm bolts holding the actuator to the compressor cover. Assuming there’s no preload on the arm, the actuator should just move freely now. Begin to tighten the adjuster nut until the point at which the actuator is held against the mounting bosses, with no free slack. This is the point of zero preload. Re-install the two 10mm bolts and tighten the adjuster nut 4 full turns.

9. A Note about Turbo Control Valve Selection

There are various ‘performance’ or ‘HD’ TCVs on the market, the majority of which are 35 series MAC industrial control valves. Since the TCV is a simple valve, which is either open or closed, there is no performance benefit to these TCVs as compared to a properly functioning stock valve. When any TCV is in the closed state, it will totally inhibit the flow of boost pressure through it, assuming it is functioning properly. An ‘upgraded’ TCV can’t stay more closed than a stock TCV. The only potential performance benefit from upgrading the TCV is a longer life span. In my experience, the MAC solenoids don’t have as long of a service life as a stock valve, which can last more than 100,000 miles.

As a turbo control valve ages, its ability to properly seal decreases. For those who noticed a performance increase from the install of one of these rebranded MAC valves, that increase was due to replacing a worn valve with a new one.

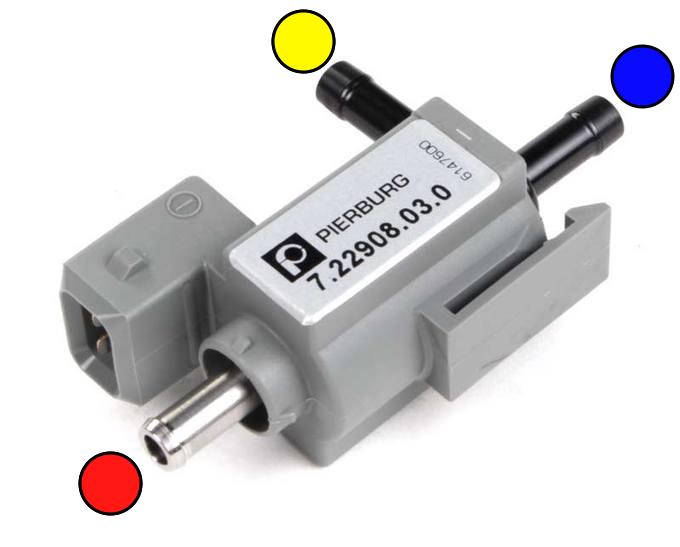

We recommend using a Pierburg 722908030 valve. This is the least expensive Pierburg TCV on the market. There are other Pierburg TCVs available, some specifically made for Volvo. Internally, these valve are all the same. It is is only the exterior plastic molding and sometimes port configuration which differs.

The port configuration for the Pierburg 722908030 valve is as follows:

Yellow – wastegate actuator

Red – turbo’s compressor cover

Blue – pre-turbo intake tube

A Footnote Regarding the Compressor Bypass Valve (CBV)

A component which sometimes gets confused as a boost control device is the CBV. The function of the CBV is to prevent the flow of boost pressure backwards through the turbo. When the turbo is producing boost and the throttle is suddenly closed, the positive pressure remaining in between the turbo outlet and throttle body wants to return to atmospheric pressure. The purpose of the CBV is to give this pressure a path that isn’t through the turbo’s compressor wheel. Without a CBV, the only path for this pressure to flow would be through the turbo’s compressor wheel. This backwards flow is called flow reversion (not compressor stall) and it is very bad for the health of the turbo. At times, the compressor wheel is spinning in excess of 100,000RPM. When flow reversion occurs, the compressor wheel is rapidly decelerated beyond 0 RPM to spinning in reverse. This puts a huge amount of strain on the turbo shaft and bearings.

There is a spring in the CBV which holds the valve shut under boost. If this spring is too weak, then the boost pressure can be limited. If the spring in the CBV is too stiff, then the CBV will not open at low to medium boost levels and flow reversion will occur at low boost levels.

There are three options for upgrading the CBV:

- IPD’s diaphragm upgrade kit

- TRITDT’s billet piston style

- Forge’s billet piston style FMDVRMR

For all of these options, the middle spring is recommended